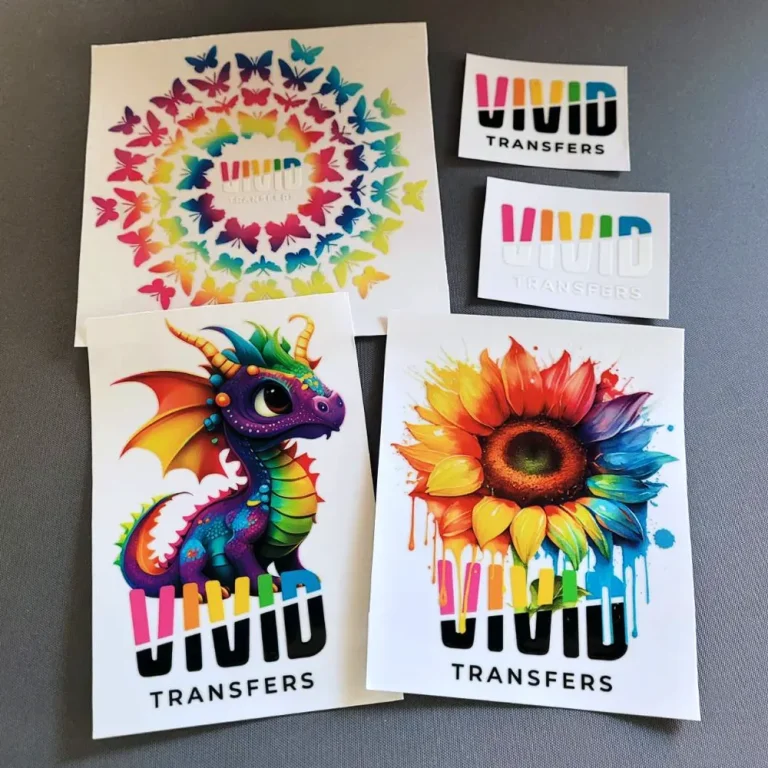

UV DTF Transfers have revolutionized the realm of custom printing, enabling creators to produce stunning designs with remarkable precision. This innovative technique, combining Direct to Film technology with UV inks, allows artists and professionals to explore an array of applications across various substrates. From vibrant apparel to intricate artwork on wood and metal, UV DTF transfers deliver durable prints that resist fading and wear over time. As you dive into this article, you’ll discover essential design tips and expert advice on effectively utilizing heat press techniques to maximize your stunning creations. Unleash your creative potential and elevate your printing projects with the extraordinary capabilities of UV DTF transfers.

Colorful Direct to Film transfers, often referred to as UV printing, are transforming how custom designs are executed on diverse materials. This advanced printing methodology utilizes ultraviolet curing technology that ensures sharp, vivid images that stand the test of time. By employing specialized heat press techniques, designers can effectively transfer these high-resolution graphics onto everything from fabrics to solid surfaces. In this discussion, we will explore essential strategies for harnessing the full potential of DTF transfers, along with design tips to enhance your projects. Join us as we unveil the secrets behind crafting durable and eye-catching prints with this cutting-edge technology.

Custom Printing Techniques Unveiled

In the realm of custom printing, various techniques have emerged to elevate the aesthetics and functionality of products. From screen printing to sublimation, each method offers distinct advantages tailored to specific needs. Screen printing, for instance, is renowned for its vibrant colors and solid coverage, making it ideal for bulk orders. Conversely, sublimation enables seamless integration of designs, allowing for full-color prints on polyester fabrics. Understanding these techniques can help artists and designers choose the most suitable method for their projects.

Each printing method, including newer innovations like UV DTF transfers, has its own unique set of applications and potential drawbacks. For instance, while UV DTF transfers provide the flexibility of printing on a variety of substrates such as fabric, wood, and metal, traditional methods may lag in the versatility department. By exploring these various printing techniques, creators can make informed decisions that align with their vision, boosting both creativity and production efficiency.

Frequently Asked Questions

What are UV DTF transfers and how do they work in custom printing?

UV DTF transfers are a cutting-edge printing technology that allows for vibrant and durable designs to be printed onto specialized film using ultraviolet inks. This method ensures that prints can be applied to various substrates, including fabrics, wood, and metal, providing exceptional resistance to fading and damage while showcasing intricate details.

How do I prepare artwork for successful UV DTF transfers?

To prepare artwork for UV DTF transfers, it is critical to use high-resolution images and vector graphics when possible, as they maintain quality when resized. Utilizing professional graphic design software like Adobe Illustrator or CorelDRAW will help in creating precise and detailed designs that translate well during the UV DTF printing process.

What equipment do I need for working with UV DTF transfers?

To successfully work with UV DTF transfers, you will need a UV printer designed for the unique inks, a reliable heat press with adjustable settings, and high-quality transfer films made specifically for UV printing. These elements are essential for producing vibrant and long-lasting custom prints.

What application techniques should I follow for UV DTF transfers?

When applying UV DTF transfers, preheating your substrate can enhance adhesion, ensuring better quality prints. It’s crucial to follow the manufacturer’s specified temperature and pressure settings on your heat press to avoid damaging the transfer or the material.

How should I care for items with UV DTF prints to ensure durability?

After applying UV DTF transfers, it’s essential to allow adequate curing time, which can range from hours to a full day, depending on ink type and conditions. To maintain the vibrancy and longevity of the prints, washing items gently and air drying is recommended to prevent premature wear.

What are the benefits of using UV DTF transfers over traditional printing methods?

UV DTF transfers offer several advantages over traditional printing methods, including immediate curing of prints for quick production, greater durability against wear and tear, and the ability to achieve vibrant, detailed designs on a wide range of substrates, making them a preferred choice for custom printing.

| Key Points | Details |

|---|---|

| What are UV DTF Transfers? | UV DTF transfers use UV inks on specialized film for vibrant, durable prints on various materials. |

| Benefits | Resistance to fading and damage; instant curing under UV light. |

| Essential Equipment | UV printer, heat press, and quality transfer films. |

| Artwork Preparation | Use high-resolution images and graphic design software for creation. |

| Printing Process Steps | Calibrate printer, conduct test prints, and adjust settings. |

| Application Techniques | Preheat substrates and set correct temperature/pressure for transfers. |

| Post-Application Care | Allow curing time; provide washing and care instructions. |

| Recent Developments | Advancements in UV DTF technology enhance quality and production speed. |

Summary

UV DTF Transfers represent a groundbreaking advancement in the world of custom printing, offering creators a powerful tool to craft vibrant and durable designs on a variety of materials. This innovative technology not only allows for detailed and striking prints but also ensures that they are resistant to wear and fading, thanks to UV ink curing processes. Entrepreneurs and hobbyists alike can benefit from the efficient methods detailed in this guide, leveraging quality equipment and careful preparation to enhance their printing capabilities. As the popularity of UV DTF transfers grows, staying updated on technological advancements and best practices will be crucial for those looking to stand out in a competitive market.