DTF transfer size has quickly become a critical starting point for designers and brands exploring Direct-to-Film workflows. Consulting a DTF transfer size guide can help standardize decisions across artwork, garment types, and production batches. In practice, the choice is often weighed against a DTF printing methods comparison, which highlights how size affects fidelity, cost, and setup times. For the Best size for DTF transfers, this guide offers practical ranges and provides a DTF transfer sizing chart to streamline decisions. By aligning transfer size with garment type and artwork complexity, you optimize image quality, production efficiency, and customer satisfaction.

Beyond terminology, the size of the transfer—often described as the print footprint or artwork scale—shapes how the design reads on different garments. Choosing the right footprint ties into fabric type, how the garment stretches, and how much room you need for color density to remain vibrant after wear. LSI-friendly terms like transfer area, print area, and artwork scale help connect this topic to related concepts such as sizing charts and method comparisons. Ultimately, adopting a consistent approach to sizing across products supports both art integrity and production efficiency.

1) Understanding DTF transfer size: the DTF transfer size guide and its impact on print quality

DTF transfer size refers to how large or small the printed design on the film is before it’s applied to the garment. The chosen size affects ink density, edge crisply, micro-detail reproduction, and the overall legibility of the image after transfer. Connecting size to image fidelity means considering how much area the ink must cover and how the garment’s surface will respond to heat and stretch. This is where the concept of a DTF transfer size guide becomes practical: it helps designers anticipate how design elements will scale across different fabrics and wear scenarios.

Beyond aesthetics, size also influences production dynamics. Larger transfers require longer press times, more precise alignment, and careful backing considerations to maintain color balance. A well-chosen size balances the artwork’s intent with the garment type, ensuring the final product reads correctly on the wearer and remains durable through wash and wear.

2) Practical size ranges for DTF transfers: matching art to apparel and best practices

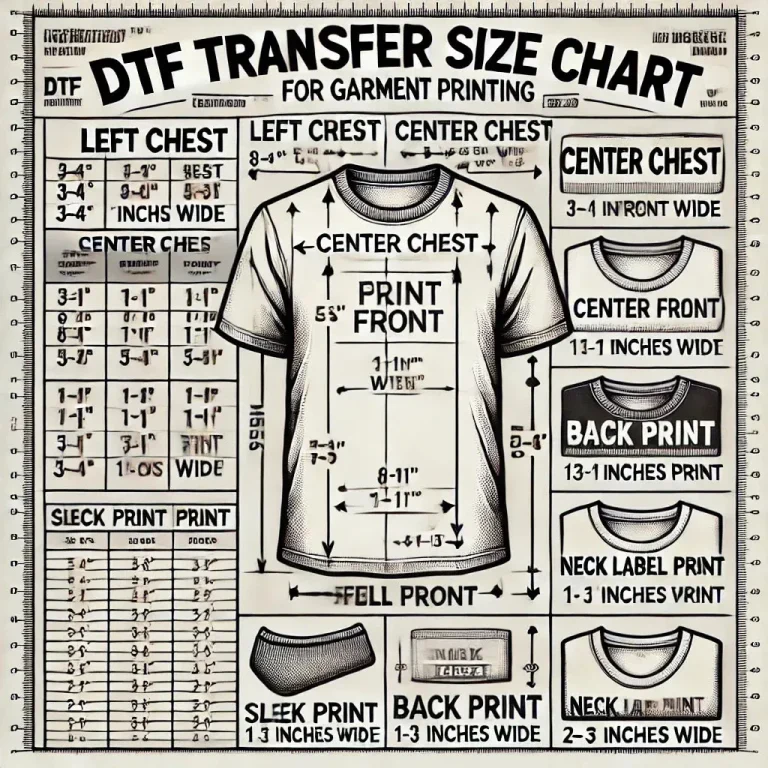

For apparel, the guide provides practical ranges that you can start with and adjust per artwork and customer needs: small logos or accents at 2–3 inches tall; left chest or pocket designs at 3–4 inches tall; medium front designs at 5–7 inches tall; full-front designs around 9–12 inches wide (or 10–14 inches tall for taller frames); and large back or all-over designs at 12–16+ inches wide or tall. These guidelines help balance visibility with wearability and avoid crowding seams or distortions during movement.

Always tailor sizes to the garment type and fabric. Cotton and cotton blends respond differently than performance fabrics or heavier fleece. Use test prints to verify readability, color density, and edge definition in real-world conditions, especially when the design approaches seams, collar areas, or stretch zones. This practical sizing approach keeps results consistent across product lines and varying customer expectations.

3) DTF printing methods comparison: how DTF transfer size interacts with screen, DTG, and sublimation

DTF transfer sizing decisions sit within a broader landscape of decorating methods. When you compare DTF printing methods, sizeability comes up as a key differentiator: DTF can offer precise color control on a per-item basis and preserve detail at moderate ink coverage, which affects how you judge optimal transfer size for a given artwork.

Compared with screen printing, DTF often handles detailed artwork more faithfully on single items or small batches, where large, uniform ink deposits aren’t feasible. Against DTG, DTF can maintain edge sharpness across diverse fabrics and colors, with transfer area carefully tuned to avoid oversaturation. When considering sublimation, note that it works best on polyester and spreads color differently; sizing must account for substrate compatibility, so DTF may win out for non-polyester or mixed-fiber garments while still requiring thoughtful size planning.

4) Building and using a DTF transfer sizing chart: turning concept into a practical tool

Creating a DTF transfer sizing chart begins with listing common garment types (t-shirts, hoodies, totes, caps) and typical print areas (left chest, full front, back, sleeve). For each area, define recommended size ranges in inches or centimeters, then add margins and alignment notes. A sizing chart helps standardize decisions, speeding up production and reducing variability across orders.

Document and update the chart as you gather data from tests and customer feedback. Include a simple mapping from artwork dimensions to target garment placements, and note any fabric-specific adjustments. This DTF transfer sizing chart becomes a living reference that supports consistent results and can be shared with the team to align expectations across projects.

5) Testing, refinement, and validation: iterating sizes across fabrics and proofs

Validation starts with preparing artwork in vector format and exporting raster proofs at multiple target sizes. Print small test runs on the same fabric and under the same heat press conditions to compare edge clarity, color density, and edge bleed. Document which sizes reproduce best for your typical customer base and which fabrics respond differently to ink density.

Next, decide on a primary size range for each garment category and keep a secondary option for special requests. Use the data to adjust the sizing guidance in your SOPs and ensure the team follows a consistent approach. Regularly revisit the tests as you introduce new fabrics or artwork styles to maintain accuracy over time.

6) Common pitfalls and best practices: mastering the Best size for DTF transfers and avoiding errors

Common pitfalls include cropping essential design elements at edges or choosing sizes that overwhelm the garment and reduce wearability. Underestimating the garment’s stretch can also make a transfer look small after washing. Differences in print size between dark and light fabrics can lower visibility if size and color density aren’t adjusted accordingly.

Best practices focus on alignment, seam awareness, and fabric suitability. Start from artwork size, scale with care, and verify legibility on the target fabric. Consider using a sizing chart to standardize placements and maintain consistency across orders. When in doubt, lean on test results and customer feedback to converge on the Best size for DTF transfers that balance aesthetics, durability, and production efficiency.

Frequently Asked Questions

What is the DTF transfer size guide and how do I use it to pick the right size?

The DTF transfer size guide provides practical size ranges and placement considerations to help you choose the right transfer dimensions. Typical starting points include 2–3 inches for small logos, 3–4 inches for left-chest designs, 5–7 inches for medium-front graphics, 9–12 inches for full-front prints, and 12–16+ inches for back or all‑over designs. Always run a test print, account for garment type and silhouette, consider margins and seams, and adjust based on artwork detail and wearer expectations.

How does the DTF printing methods comparison inform transfer size decisions?

DTF printing methods comparison helps you see how size interacts with different decorating techniques. Screen printing is efficient for large runs but less flexible for small or highly detailed work; DTG can struggle with color density on dark fabrics; sublimation has substrate limits. In contrast, DTF transfer sizing decisions focus on edge clarity, ink density, and accurate alignment, with broad compatibility across fabrics.

What is the best size for DTF transfers for different garment types?

Best size for DTF transfers varies by garment. Small logos: 2–3 inches; left chest: 3–4 inches; medium front graphics: 5–7 inches; full-front prints: 9–12 inches; back or all-over designs: 12–16+ inches. These guidelines depend on garment size, fabric, and wearer expectations, so always validate with test prints.

How should I think about DTF transfer by size vs other methods to optimize results?

DTF transfer by size vs other methods means weighing how size impacts edge definition, ink density, and color balance across techniques. DTF generally allows precise color control on a wide range of fabrics and works well for single items or small batches, while screen printing excels in high-volume runs and sublimation suits certain substrates. Always test proofs to ensure legibility and balance for your chosen method.

How can a DTF transfer sizing chart improve consistency and planning in production?

A DTF transfer sizing chart standardizes placement and size across products. Build it by listing garment types and typical print areas, then map recommended size ranges, margins, and alignment notes. Use test results to refine the chart and document it in internal SOPs so all team members apply consistent sizing during production.

What practical steps should I take to implement a solid DTF transfer size plan in my workflow?

Start with vector artwork and export proofs at multiple target sizes. Run small test prints on the same fabric and press conditions, then evaluate edge clarity, color density, and alignment. Decide primary and secondary sizes per garment type, document the guidance in SOPs, and train staff to apply the sizing plan consistently across orders.

| Aspect | Key Points |

|---|---|

| What is DTF transfer size? | The size refers to the printed design on film before transfer; it affects color density, edge clarity, micro-detail, and how the design reads after application. |

| Why size matters | Affects ink volume and film area, color balance, edge clarity, how much of the design remains visible after wear, and impacts pressing time and alignment needs. |

| Design balance | Size should balance design intent, garment type, and practical constraints; e.g., tote vs. small pocket print. |

| Practical size ranges (apparel) | Small logos: 2–3 in; Left chest/pocket: 3–4 in; Medium front: 5–7 in; Full-front: 9–12 in wide or 10–14 in tall; Large back/all-over: 12–16+ in. |

| Fabric considerations | Assumes standard cotton/cord blends; other fabrics may behave differently; test first. |

| DTF vs. other methods | Compared to screen printing, DTG, and sublimation, size decisions depend on method constraints; DTF often allows precise color control per item. |

| Testing and iteration | Test prints help adjust size, ink density, and transfer technique across fabrics. |

| Practical sizing tips | Start with vector art, consider garment fit, account for margins, plan color/ink coverage, and use a sizing chart. |

| Sizing chart concept | Create a chart mapping garment types and print areas to size ranges with margins and alignment notes. |

| Workflow | Prepare vector artwork, export proofs, run test prints on the same fabric, evaluate results, set primary/secondary sizes, document in SOPs. |

| Common pitfalls | Cropping, overly large prints, underestimating stretch, and fabric color interactions require adjustments. |

Summary

DTF transfer size is a practical design parameter that influences readability, color fidelity, durability, and production efficiency across fabrics and garments. This descriptive overview explains how size interacts with fabric type, artwork complexity, and workflow, and provides practical guidelines to help you select sizes that maximize legibility and wearer satisfaction while minimizing waste and misprints. Start with vector artwork, test across multiple fabrics, and build a DTF transfer sizing chart tailored to your products to scale artwork from small accents to full-front designs with confidence. In short, thoughtful DTF transfer size decisions enable consistent, high-quality results and efficient production.